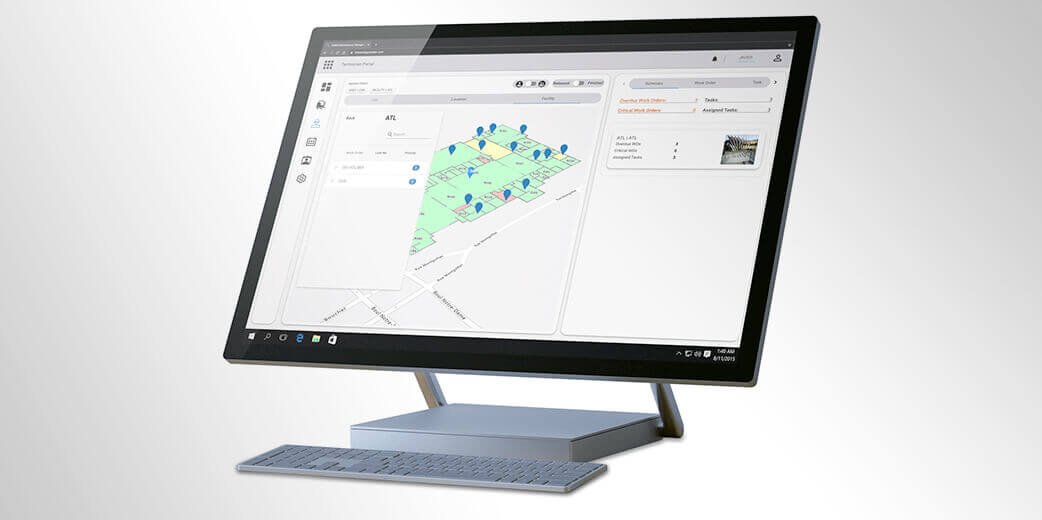

TAG Geographic Information System for maintenance management

Visually and easily track your work orders and assets with TAG’s advanced GIS map feature.

What is TAG GIS?

TAG’s advanced GIS feature is built to facilitate maintenance processes and communication between technicians and team members who initiate work orders. TAG can automatically position all of your equipment on a map simply by using the coordinates of your equipment and facility as well as CAD drawings. When maintenance technicians receive a work order on their mobile devices via TAG’s Mobility Suite, they can use TAG GIS feature to view their location, as well as the equipment’s location and image. They can drill down from there to access vital information on the faulty equipment, such as past maintenance, warranties, etc. What’s more, thanks to TAG GIS, technicians can view all current work orders around them by priority and area in a plant—and provide additional assistance to other crews, if required.

What can companies and maintenance teams achieve with TAG GIS?

Quickly locate faulty equipment in the field

Coordinates on equipment cards precisely position assets on the map so that they appear as icons, with a color that represents each type of equipment. A pop-up hovers on top of the icons to provide more information for technicians.

Easily process transactions directly from the map

Work order requesters and technicians can access equipment cards by choosing the equipment right on the map, and thereby process requests or complete work. Users can also have access to all equipment information and statistics based on their roles and security permissions.

Visually track all assets per room in your facility

Visualizing your equipment in each room and in each floor of your facility, with accurate drawings, locations and asset information, can significantly accelerate your maintenance processes.

Use an interactive map to efficiently access actual maintenance data

Seeing your equipment and facility on a map is one thing. But imagine accessing a wide range of maintenance information from that map, such as critical work orders under completion, unattended issues, and more. Click on a specific piece of equipment to view all related information.

Create equipment and its geographical coordinates on the fly

Technicians can easily create new equipment from scratch or a template, or duplicate it from another existing asset. Assign a barcode by scanning it with a mobile device camera or create an intelligent QR code to stick on the equipment. TAG GIS can then connect to the mobile device’s GPS to automatically insert the equipment’s coordinates.

Facilitate communications with your customers

If you execute maintenance as a service (MaaS), you can use TAG GIS to help customers visualize equipment in their facilities or out in the field—either for their own workflows or to simplify the communication process with your team.

Leverage 3D CAD drawings as you transition to IoT and Artificial Intelligence

You can use your 3D CAD drawings of your equipment and facility in TAG GIS to take the first step towards monitoring your equipment int real time and in virtual reality thanks to its direct link to TAG IoT. By using the Linear feature, you can view the sequential impact of an initial downtime of a piece of equipment on your other assets.

Keep track of your workforce

By adding IoT and route optimization features in TAG EAM, you can track your technicians’ devices live on the map. Easily pinpoint the closest available technicians to a new work order that has just came in and proactively communicate with them to ensure quick dispatching.

TAG GIS for asset management enables you to harness the power of multiple layers of asset data on map to boost your maintenance team’s productivity and performance.